More and more, prototypes as well as production parts and products are now being produced using additive manufacturing instead of traditional injection molding. With that being said, tests of these 3D printed items are essential for comprehensive product design and improvement. Physical characteristics must be determined for each material used by a 3D printer for a project, each 3D printer that uses that material, and for each orientation of the print. Additive manufacturing testing is key to provide the knowledge of how materials work and how designs can be improved for more reliable products.

ARL’s Additive Manufacturing Tests include General Reliability, Deflection, HALT/HASS, Shock & Vibe, Salt Fog, IEC 60529 Standard, Altitude, Temperature & Humidity and UV & Solar.

While our lab has a wide range of equipment to support all of the tests listed above and more, ARL also features specific equipment to meet your additive manufacturing testing needs, including the following:

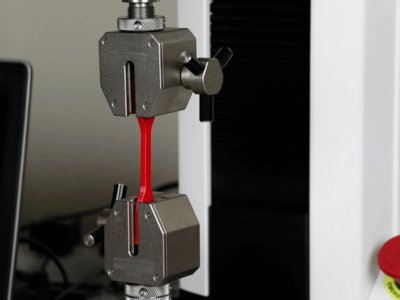

- MARK-10 ESM750S Tensile Tester – The MARK-10 Tensile Tester is a single-column force tester configurable for tension and compression measurement. Tensile Testing is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. For 3D printed products, the tests performed using the MARK-10 are commonly used to select a material for an application, for quality control and to predict how a material will react under other types of forces.

- Hexagon Romer Absolute 3D Scanner – The Hexagon Romer Absolute Arm with Integrated Scanner 7725SI (RS4) is an all-purpose, portable 3D measurement tool for digitization, inspection and analysis. This metrology system captures 3D point data from a wide variety of surface types and can be utilized in almost any measurement application.

- Phase II+ Rockwell Hardness Tester – Hardness is a material’s resistance to indentation. The Rockwell hardness test method measures the permanent depth of an indentation created by a load applied to a material. Different indenters, such as diamond and ball indenters, can be used during this process depending on the test material.

When it comes to testing your 3D printed items, think of ARL for your additive manufacturing testing needs. Contact our staff today and let us determine the most appropriate testing profile for your product.

ARL is here to help with your additive manufacturing projects. Our lab can fully test your 3D printed items for the following:

- Ultimate Tensile Strength

- Yield Point

- Young’s Modulus

- Failure at Bend

- Failure at Compression

- Coefficient of Friction

- Aging

- Deflection

- Creep

- Shear

- Hardness

- Surface Texture

- 3D Scanning

- 3D Metrology

VIDEO GALLERY

PEOPLE

Dedicated expertise working for you.

PARTNERSHIP

Successful business is a series of interlocking personal commitments.

PROCESS

Focused on innovation, entrepreneurship and community.

PURPOSE

Built to last, a proud member and resident of the community we serve.