Mechanics have been around since the first hominid started using stone tools. Even so, this area is a complex, detail-oriented science, and it takes knowledgeable, detail-oriented people to properly test. At ARL we have years of experience in Mechanical Testing and can help you isolate problems or verify specifications. Our lab performs a variety of mechanical tests, including:

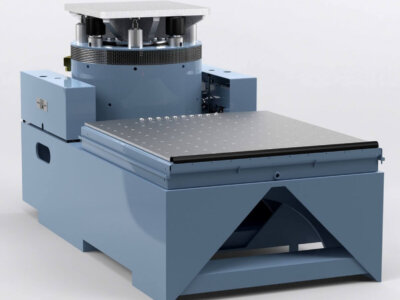

Shock and Vibration Testing – Shock and Vibration Testing is useful in several stages of product manufacturing. The vibration testing process can be utilized in the design development, qualification and production stages.

In the product design stage, vibration testing allows for discovery of weaknesses in a design prototype. During product qualification, testing can determine the adequacy of a product for a specific application or range of applications. When the prototype moves from the testing laboratories and into the production stage, the quality of the final product can be evaluated by shaker systems. This final component testing can be done by using both destructive and non-destructive techniques.

Check out our recent custom vibration test – our team was able to combine our expertise in mechanical, environmental and additive manufacturing testing to help a client during the product development process.

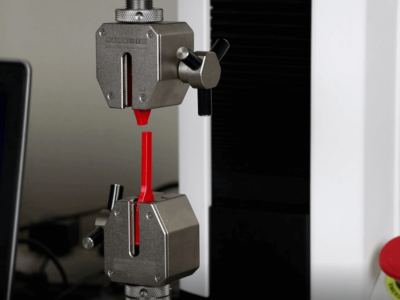

Tensile and Compression Testing – Tensile Testing is a fundamental materials science test in which a sample is subjected to a controlled tension until failure. The results from the test are useful in selecting a material for an application, for quality control and to predict how a material will react under other types of forces. Our team can perform Ultimate Tensile Strength, Compressive, Flexural Strength, Creep, Shear, and Coefficient of Friction testing.

Drop Testing – Drop Testing determines the ability of a package or product to withstand the stresses of handling drops by people and machinery in both the distribution and use environment. Our drop test system allows you to thoroughly examine the effectiveness of package cushioning and its ability to protect your product. Testing also allows for examination of other critical design attributes by exposing your product to all possible drop test orientations.

Hardness Testing – Hardness is a material’s resistance to indentation. The Rockwell hardness test method measures the permanent depth of an indentation created by a load applied to a material. Depending on the test material, hardness testing utilizes different indenters, with diamond indenters used for harder metals and ball indenters used for softer materials.

Mechanical Fatigue – The team at ARL frequently designs specialized test apparatuses to evaluate product mechanical fatigue, wear-out and end-of-life. This is extremely beneficial in order to determine product performance and life expectancy of the mechanical aspects of your product.

Contact us today in order for us to determine the appropriate standard for your product!

VIDEO GALLERY

PEOPLE

Dedicated expertise working for you.

PARTNERSHIP

Successful business is a series of interlocking personal commitments.

PROCESS

Focused on innovation, entrepreneurship and community.

PURPOSE

Built to last, a proud member and resident of the community we serve.